Waste water, carbon emissions, river pipeline and roading changes were some of the issues covered at Fonterra Hautapu’s annual meeting with its community last month.

All bar a couple of seats at the factory’s training rooms were occupied as Environmental manager Jude van Bommel welcomed residents and used the next hour to bring them up to speed on the site’s activities.

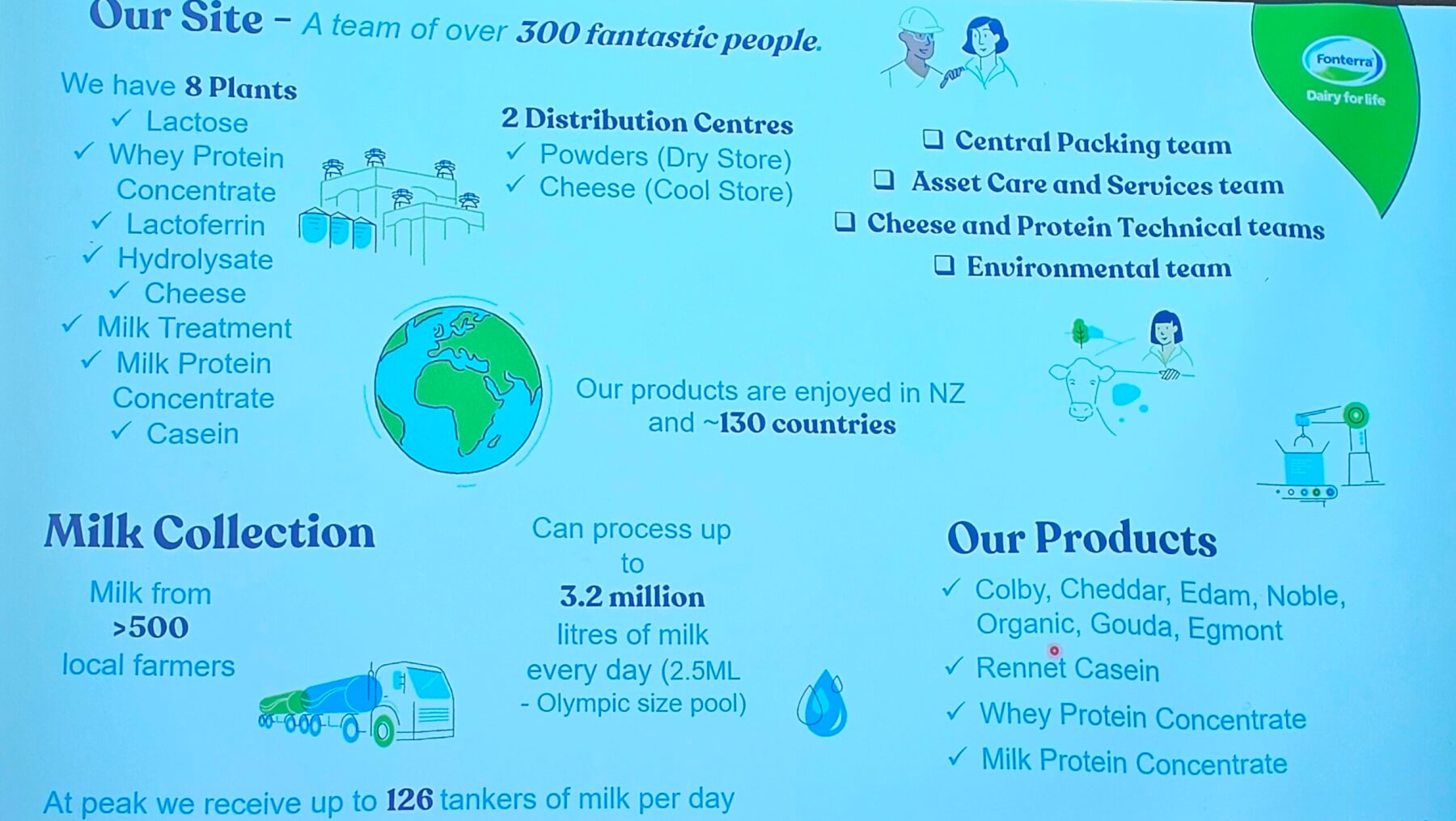

The story of Fonterra Hautapu dairy factory.

Hautapu specialises in producing high-value products – for example, casein, lactoferrin, hydrolysates and whey protein concentrate.

A factory has been on the site since 1884 and 140 years later continues to expand.

It now employs 300 people in eight plants and has two distribution centres.

The factory receives milk daily from more than 500 dairy farmers and 126 tankers and can process up to 3.2 million litres of milk a day.

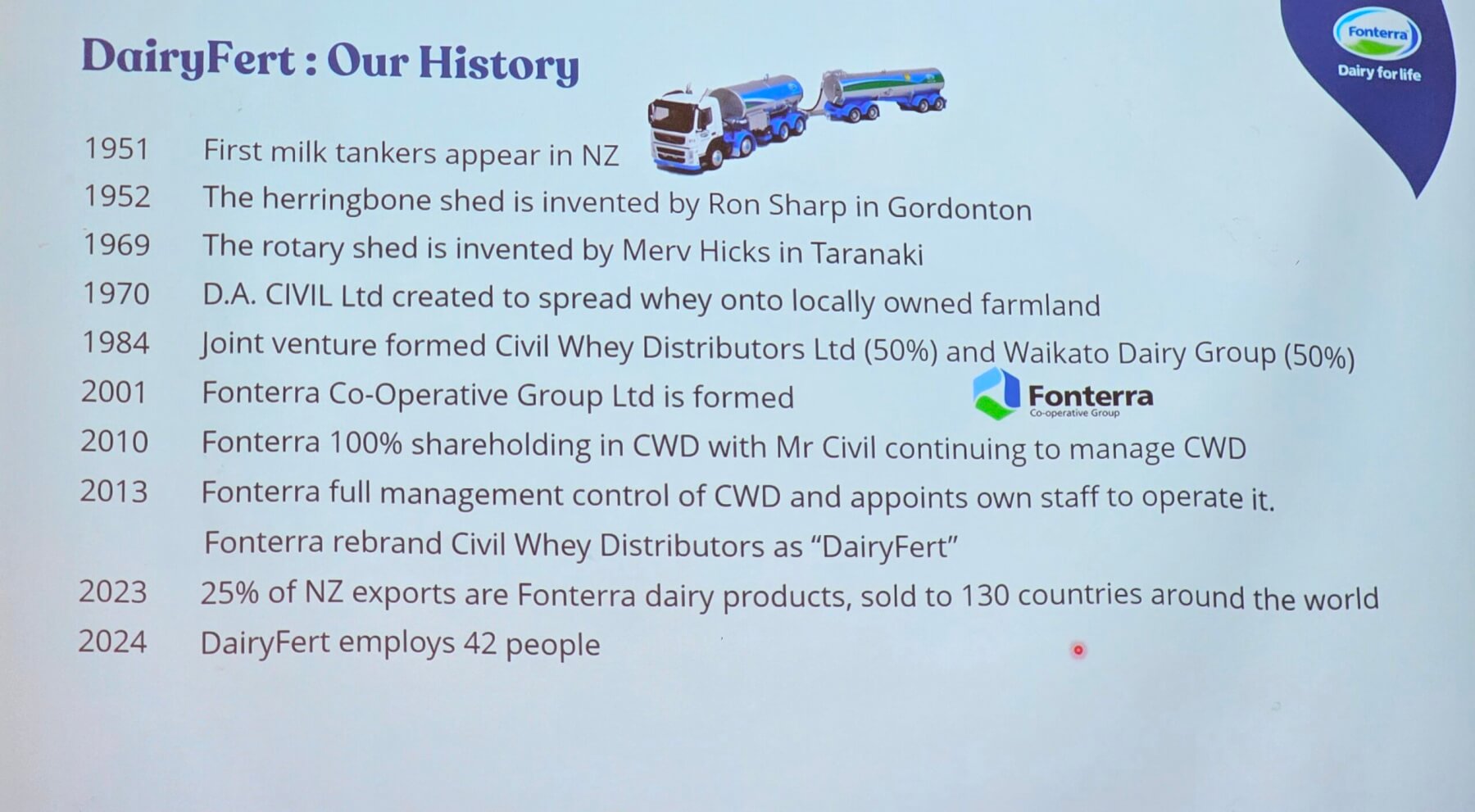

The session included an update from Fonterra subsidiary DairyFert which manages all the dairy liquids generated by Fonterra’s Waikato manufacturing sites.

Fonterra owns three nearby stockless farms: Bruntwood, Buxton and Bardowie farms, where they grow crops from the by products to distribute to Fonterra farmers. The by products also go to stockfood for animals.

DairyFert has added new equipment to help spreading operations – a mobile nurse tank and an umbilical system which allows for quick and efficient by product spreading.

Van Bommel said the factory reported three incidents to Waikato Regional Council this season.

Dairy Fert history

They were an odour from paddocks following a silage cut, a riverline leak in Peake Road and a missed paddock line flush.

Work has started on the controversial $85 million wastewater treatment plant which will treat process wastewater from the manufacturing plant. Construction is expected to be finished by March next year.

When the company announced its intentions three years ago, there was widespread opposition from neighbours. Waipā District Council granted consent in April 2022.

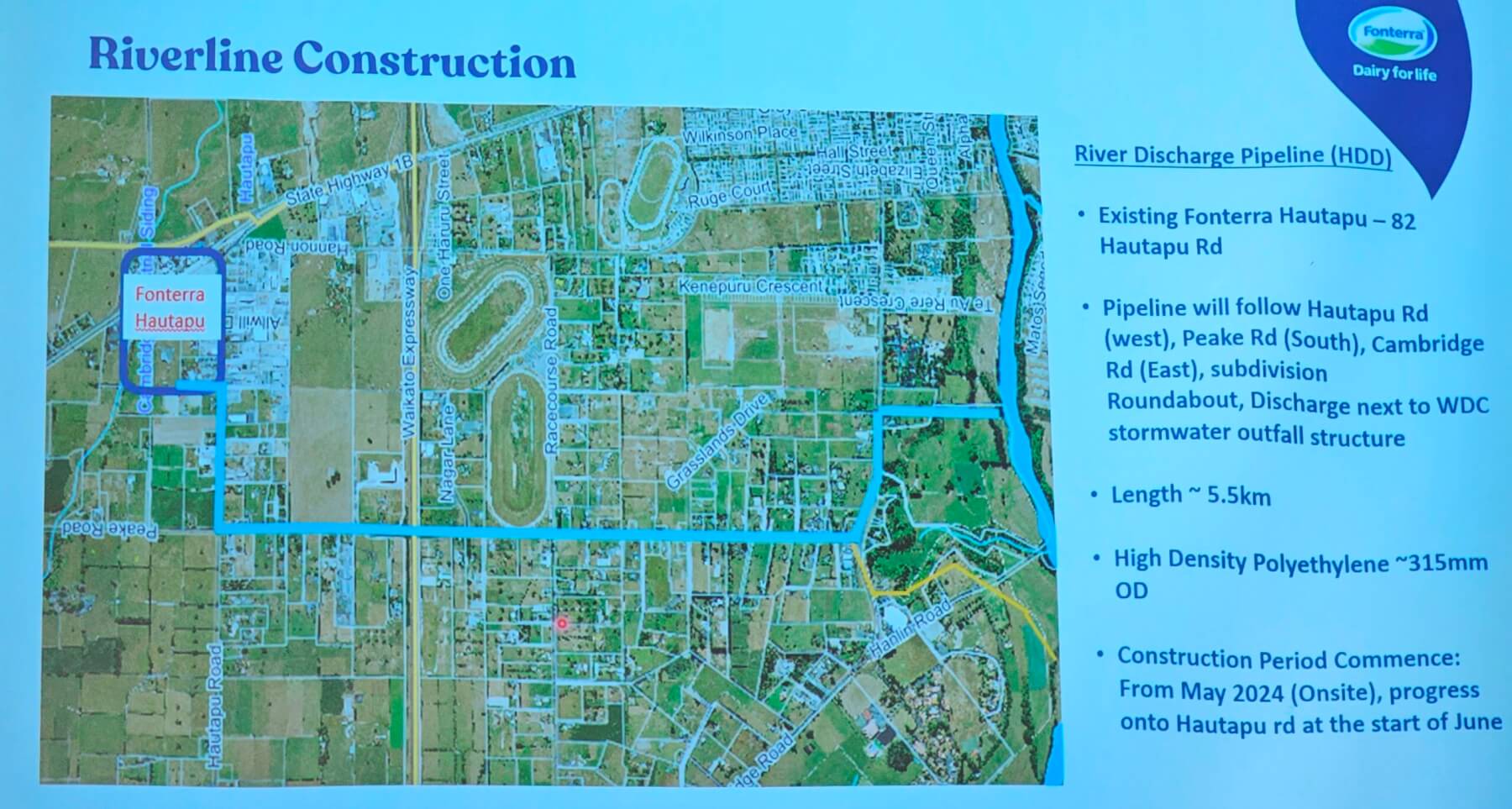

To support the plant, construction began last month on a new river pipeline to discharge treated waste into the Waikato River. The line will leave the factory and travel west along Hautapu Road, then south along Peake Road to the new Cambridge Road subdivision and roundabout and then discharge next to Waipā District Council’s stormwater outfall structure.

Work on decarbonising its operations at Hautapu is well underway and will see coal-fired boilers go and replaced by wood pellets.

Once complete, Hautapu will reduce Fonterra’s carbon emissions by a forecasted 15,785 tonnes per year – the equivalent of taking about 6500 cars off New Zealand’s roads – and see a 25 per cent reduction in CO2 emissions.

River line construction for Fonterra Hautapu.

The wood pellets are made from sawdust and shavings compressed using heat and pressure to make a pellet.

The boiler conversion construction began last month, and all boilers should be live by next month.

Boiler conversion at Fonterra Hautapu.

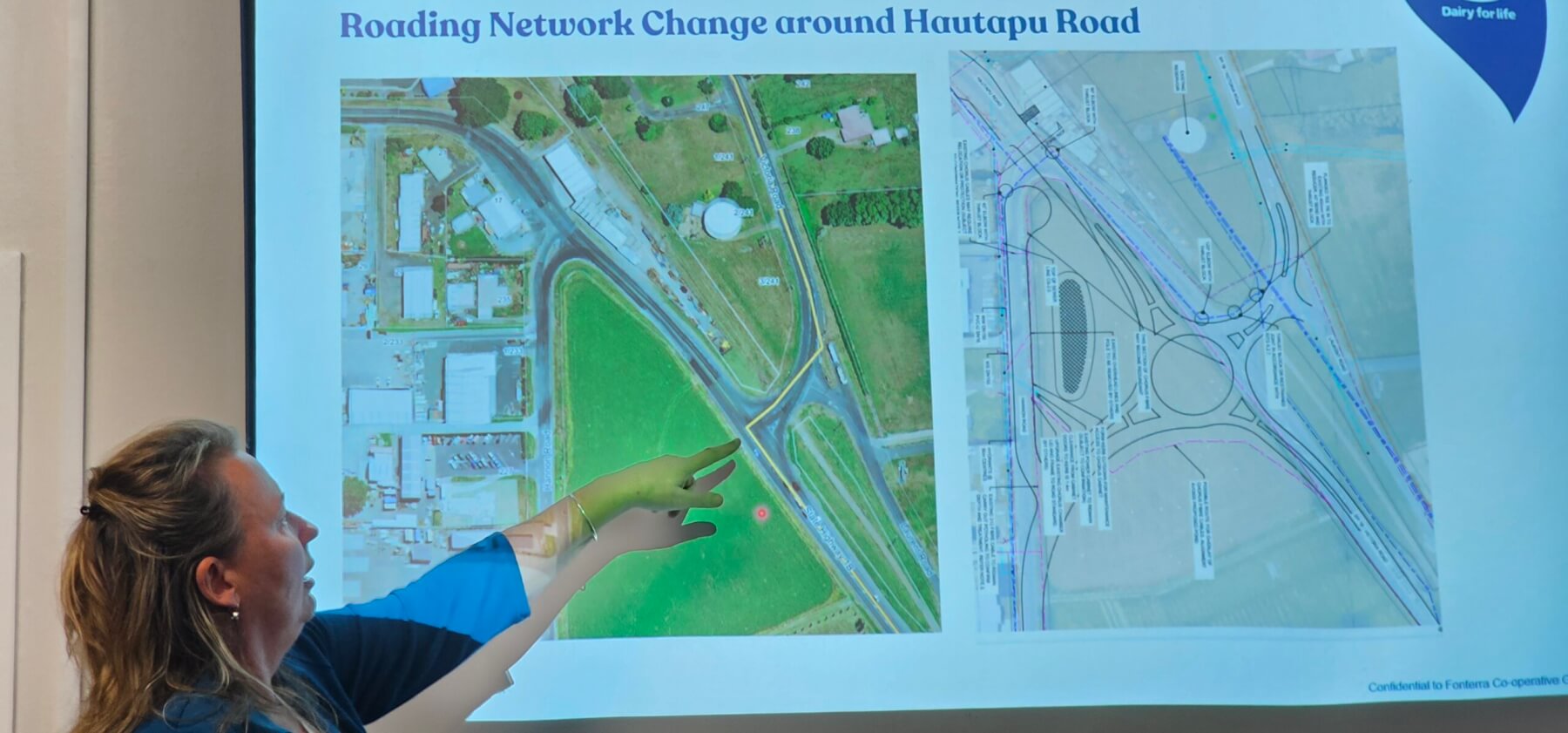

All the work has required roading changes around Gate One in Hautapu Road – a date has yet to be confirmed – and the construction of a new roundabout on nearby Victoria Road.

Waka Kotahi New Zealand Transport Agency also plans to replace a culvert on SH1B just south of the intersections with Bruntwood and Zig Zag roads.

Future consultations by Fonterra include a plan change for the dairy company’s Bardowie farm from rural to industrial.

For supper, attendees were treated to the gold medal winning Hautapu mature organic cheddar which picked up the award at the recent New Zealand cheese awards. Also available was the factory’s Gouda M.

Fonterra Hautapu Environmental manager Jude van Bommell points to some of the roading changes needed near the site. Photo: Mary Anne Gill.